- Home Page

- Company Profile

-

Our Products

-

TTR Slitters

- Manual TTR Slitter RSDS2

- Manual TTR Slitter RSDS4

- Semi-Auto TTR Slitter RSDS2 Plus

- Semi Automatic TTR Slitter RSDS5 Plus

- Automatic TTR Slitter RSDS6 Plus

- Fully Automatic TTR Slitter RSDS8 Plus

- Automatic TTR Slitter RSDS8H Plus

- High Speed Slitter

- Film And Paper Slitter

- 1350 Film and Paper Slitter

- 750mm Film and Paper Slitter

- 1350 1600 Film and Paper Slitter

- ATPA 60R Auto Packing Machine for TTR

- C1600 Auto Foil Roll Cutter

- CRTR110 Card Print Ribbon Rewinder

- CRTS750 Card Print Ribbon Slitter

- Film and Paper Rewinder 750mm

- Helping Machines

- Manual Foil Roll Cutter

- Mini Slitter 250mm

- Mini Slitter 300s

- Mini Slitter 350MM

- Mini Slitter 450 450s

- NCM 260 Helping Machines

- PCA 1500 Helping Machines

- PCM 1000 Helping Machines

- PCS 1500 Helping Machines

- RSDS1 RSDS2 Manual TTR Slitter

- RSDS4 Manual TTR Slitter

- RSDS5PLUS Semi Auto TTR Slitter

- RSDS6PLUS Automatic TTR Slitter

- RSDS8PLUS RSDS8HPLUS Automatic TTR Slitter

- Semi Auto TTR Slitter

- Foil Slitter

- Mini Slitter

- Paper Core Cutter

- Paper Core Notch Cutter

- Slitter Rewinder machine

- Barcode Ribbons

- Slitter Blade Holders

- Foil Roll Cutters

- Paper Core Loading Machine

- Mini Trolley

-

TTR Slitters

- Quality Assurance

- Contact Us

Showroom

Be it graphic cold and hot foils or thermal transfer ribbon, our offered array of TTR Slitters includes slitting machines that can be used for both purposes. This is an ultimate solution to slit jumbo rolls into finished ribbons. With easy handling, the mentioned range of slitter helps in ensuring maximum benefit out of the process of production.

Ergonomically developed Foil Slitter is used for maintaining cutting precision of PVC, BOPP, PET films; aluminum foil and kraft paper. Available in hand controlled or mechanically regulated operating mode based options, this low cost machine is user friendly. Its operating cost is also low.

The mentioned range of Mini Slitters includes simple and basic slitter with minimal features that allow a user for processing small rolls. This type of slitter commonly find application to cut the base material of appropriate width so that the process of manufacturing vertical blinds can be carried out in a correct manner.

Our offered range of Paper Core Cutters are designed for cutting large amount of paper at once without any irregular edges. Cores of paper can be easily cut with different diameters, thicknesses and lengths. This cutter is an ideal choice for the people who desire bespoke solution for fulfilling their cutting requirements.

Get professional looking patterns without making any efforts with the help of our offered Notch Cutters. This range helps in making the notching simpler by making accurate notches by easily lining up the edges of pieces of pattern. This helps in appropriate fitting of these patterns. The mentioned Notch cutter is an ultimate solution for pattern cards, craft hobbies, garments, etc.

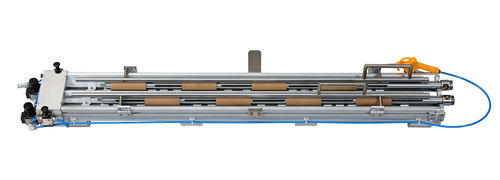

Slitter Rewinders are machines that helps in the conversion of large rolls of various material such as adhesive films into smaller ones in terms of either diameter or width. Featuring manual setting of blades, rewinding arms and slit reels unloading, the mentioned range is widely demanded in the packaging, print and converting industry.

Barcode Ribbons does not only find usage in printing bar codes using barcode printers but for logo, symbols, numbering, words and many more things. Errors related to data entry can be easily reduced with the help of barcode ribbons while speeding up the work processes.

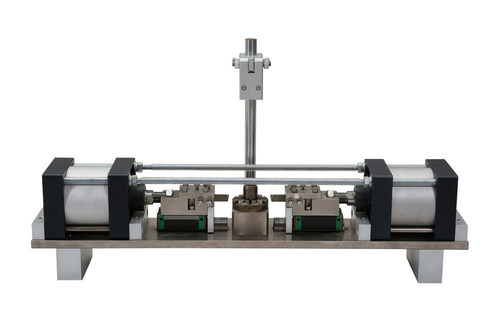

Slitter Blade Holders are designed with modular mounting features for allowing retrofit to different machines. Featuring air purged and dust-proof design with simplified controls to have pneumatic operations. The mentioned range also includes quick clamp blade holders for easy installations and maintenance. These holders are sturdily constructed using die-cast metal to withstand harsh industrial conditions.

Foil Roll Cutters helps in cutting the long foil into the desired size. This cutter is beneficial as it grips the foil internally for the prevention of damage that may occur to the foil during cutting. The mentioned range is designed to have ease in the usage of foil and avoid wastage by rendering smooth cutting.

This Paper Core Loading Machine is used for easy loading and unloading of papers. It is precisely manufactured under the stern observation of dexterous professionals by making use of quality approved components. Well known for its unmatched performance, noise free operation, energy efficiency and easy operation, this machine is demanded in paper mills. Finally, it is carefully tested by our quality inspectors to make sure that every component of this machine is faultless.

Offered hydraulic Mini Trolley is used for smooth relocation, loading and unloading of cargo. Steel frame of this trolley is welded and is powder coated to avoid rust. Hydraulic pump of this trolley has prolonged service life. Heavy load bearing capacity is one of its main features.

|

XIAMEN DELISH AUTOMATION EQUIPMENT CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |